DTF-specific ink

original Japanese ink Eliminates ejection failure

in low-temperature and low-humidity environments Check

Ink replacement kit

Uses an aluminum pouch to prevent deterioration of the ink!

High quality original Japanese ink

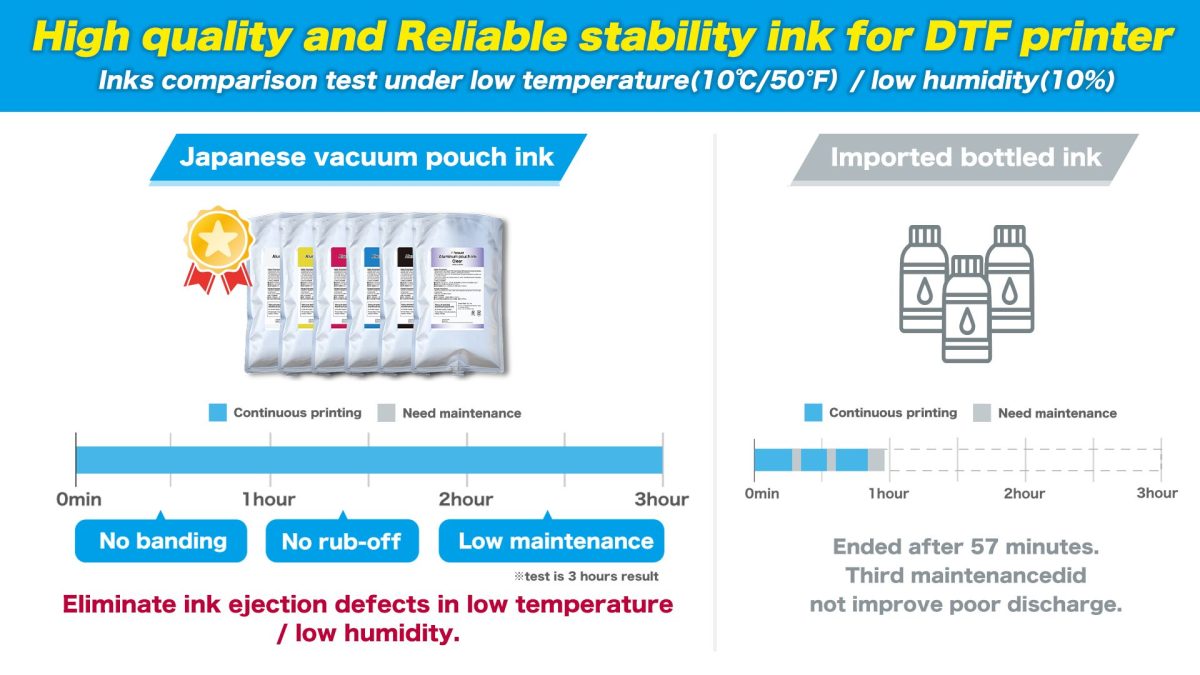

DTF printers have a problem as a poor ink ejection, especially when temperatures and humidity decrease, particularly in autumn and winter during seasons like autumn and winter, during autumn and winter.

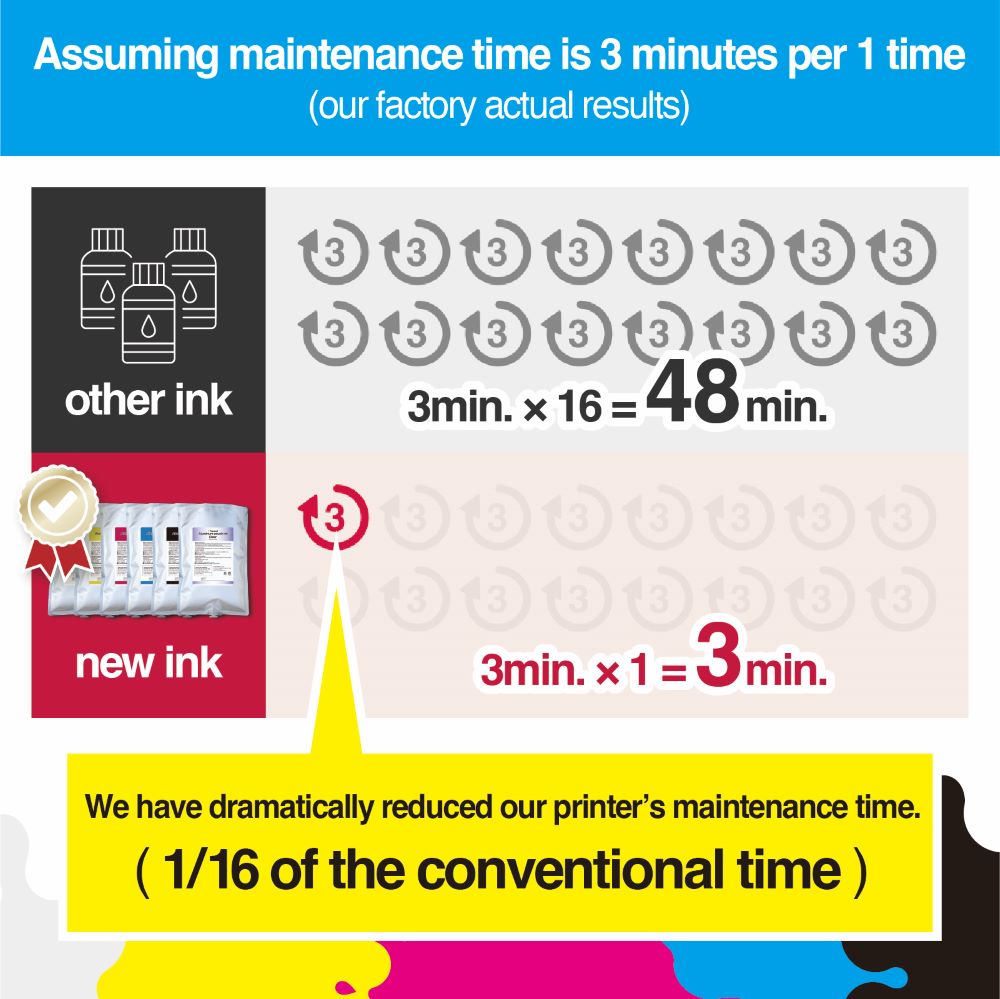

Reduce maintenance time

Our pouch inks have a result in a 1/16 reduction in maintenance tasks per day compared to the imported ink we used previously.

Good white ink density

*Comparision of white density between a imported bottled ink and our pouch ink.

- ・No chemicals banned in the U.S. and Europe

- ・Vacuum-packed ink

- *Preventing deterioration: Ink deteriorates more quickly when it is exposed to air.

- *There is no need to worry about bubbling even if the ink is shaken vigorously.

- ・Stable ink quality

- *Whether the ink production process and component like resin are properly controlled.

- ・Excellent re-dissolubility at a head nozzle

- *That contributes to recovery and longer life by re-dissolving even after drying at the head nozzle.

- ・High white density for improved reproducibility

- ・No fading or cracks when washing

- In the case of bottled ink , the ink vaporizes and air dissoloves into the ink. The temperatre change then causes the dissoloved air to come out and clog the printer head.

- ・Certified by Oeko-Tex ECO PASSPORT

[Safety Precautions]

- ・Shake pouch inks about 100 times (about 90 seconds) every day before starting work to ensure the content is distributed in it evenly.

- ・The shell life for the ink is 12 months from the date of production, please use it up within the date.

- ・If your skin comes into contact with ink, wash the affected area thoroughly with soap and water.

[Storage Precautions]

- ・Store ink packs in a cool, dark place keeping away from fire and high temperatures.

- ・Keep out of children’s reach.

[Setting/Installment]

- Ink replacement kits are also available.

- The replacement of ink units is very straightforward.

- Insert the joint component (tube/connector) into the pouch ink and use an S-shaped hook to hang the pouch.

- Simply change the ink supply!

- Simply reconnect the current ink tubes!

- *There might be some compatibility with your DTF printer.

Please feel free to ask if you have inquiry.

Eliminates poor ink ejection

in low-temperature and low-humidity environments

The feature of banding in DTF prints

The common DTF ink contains a lot of resin components. Depending on the quality and amount of resin, the risk of head clogging will increase and banding is likely to occur more than other printer inks. If banding occurs frequently, the head cleaning maintenance will be required repeatedly, and it affects productivity. Also, if the ejection failure does not improve even after cleaning the head, the head will need to be replaced, which can be very costly depending on the frequency of occurrence.Banding due to clogged heads occur especially when the temperature and humidity decrease, the season like autumn and winter.

Conducted DTF ink tests in a laboratory that reproduces a low temperature (10°C) and low humidity (10%) environment

“Japan-made vacuum pouch ink” vs. “Imported bottled ink” DTF ink comparison test under low temperature and low humidity environment

4 key point of ink stability

1. Component

DTF ink contains a resin. The binder powder, which melts with heat, is attached to this resin. Therefore, the more resin, the easier it is for the ink to adhere and the stronger the transfer adhesion, but the risk of head clogging increases depending on the quality and quantity of the resin. In Japanese vacuum pouch ink, the components contained in the ink are properly controlled.2.Shell life manage

Since ink deteriorates gradually, the month of manufacture and the storage environment must be properly managed. An ink that it’s unsure when manufactured may has a risk of problems occurring at some point. Especially in the case of imported ink, the storage period and shipping date may be unknown, and furthermore, the ink may be imported through the harsh environment during shipping by ship, which increases the risk of problems occurring. Our ink manege the month of manufacture and the storage environment are controlled, so the above risks are reduced.3.Vacuum-packing

“Preventing deterioration by not exposing it to air” is important, but there are 4 points more.

①Prevents the generation of bubbles during stirring DTF ink requires regular stirring because the components contained in it settle out. Depending on the type of filter, the bubbles will clog the filter if it foams during stirring, but if it is vacuum packed, it will not foam even if it is vigorously shaken.

②Prevents the dissolution of oxygen If DTF ink is exposed to air, oxygen will dissolve in the ink with a decrease in temperature. This Dissolved oxygen becomes air bubbles with a rise in temperature, which clog the print head and cause printing defects.

③Prevents the evaporation of water If the ink is exposed to air, it will be affected by its environment and the water in the ink will evaporate. As this water evaporates, the density of the ink changes and fluidity deteriorates, affecting the head.

④Prevents the influence of humidity The resin contained in the ink may separate from the ink due to humidity. Due to this separation, the resin has a large effect on clogging the head, but vacuum packing can prevent the effect of humidity.

4.Quality / Stability

Some imported inks are not always known information regarding quality like “management during ink production” and “correctness of ingredients for each ink” etc.. In fact, when we analyzed the composition of imported inks, we found that the water content vary from manufacturing lot to lot. This is probably due to the evaporation of water from the ink, but if the ink is vacuum-packed, the quality can be prevented from changing.Pouch ink replacement kit set

Try Japanese high-quality DTF specific-ink.